Different between Three plate mold and two plate mold

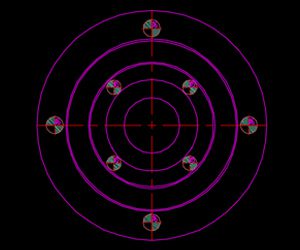

Three plate mold has more cut runner plate than two plate mold, it is pin-point gate, with good look for visible surface. The most important is that it could ensure the part perfect round. It usually make 3 points, 6 points or 12 points gate.

Product Details:

- Product name: SP1640

- Industries: Industrial

- Mold Standard: HASCO

- Steel: NAK80 48-52HRC

- Cavities 1 x 1

- Plastic: PA6+30%GF

- Runner system: Cold

- Cycle time: 120s

- Gate: 6 pcs pin-point

- Dimensions: 300 X 350 X 400mm

- Mold life: 500,000 shots

- Lead time: 4 weeks

Description:

Mold design for round part, 6 pcs pin-point solution, HASCO standard, 1.2344 steel apply in industry

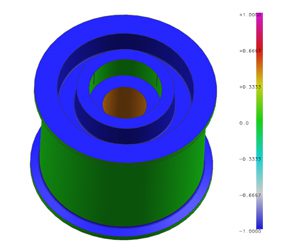

1. Part Size: Φ80 x 58 mm & Draft Analysis

2. Gate location: 6 pcs Pin-point gate Sprue Sr. is Φ1.5mm.

3. Ejector system & Cooling system

4. Venting

Mold Design

Mold design is including DFM, Mold Flow Analysis, 2D Mold Layout and 3D Mold Drawing. It is part lay out, part line making, gate design, runner design, gating way, ejection method, cooling layout, etc.