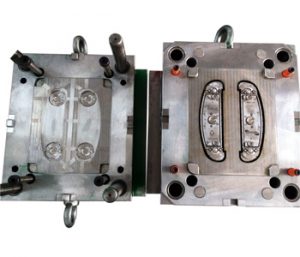

Different between 2 cavity & 1 cavity mold making

2 cavity mold here is three plate mold, it could be two plate mold too. I cavity mold is offset spruce mold. As it is edge gate.

Product Details:

- Product name: X61A1846

- Industries: Industrial

- Mold Standard: HASCO

- Steel: S136 HRC 50-54

- Cavities 1 x 2

- Plastic: PA6+30%GF

- Runner system: Cold

- Cycle time: 85s

- Gate: 4 pcs pin-point

- Dimensions: 400 X 400 X 350mm

- Mold life: 500,000 shots

- Lead time: 4 weeks

Product Details:

- Product name: X61A1846

- Industries: Industrial

- Mold Standard: HASCO

- Steel: NAK 80 HRC 38-42

- Cavities 1 x 1

- Plastic: PA6+30%GF

- Runner system: Cold

- Cycle time: 55s

- Gate: edge

- Dimensions: 250 X 400 X 300mm

- Mold life: 300,000 shots

- Lead time: 3 weeks

1.Part Size: 201.28X63.00X30.70mm & Draft Analysis

2. 1 cavity & 2 cavities mold

3. Molded part

Mold Design

Mold design is including DFM, Mold Flow Analysis, 2D Mold Layout and 3D Mold Drawing. It is part lay out, part line making, gate design, runner design, gating way, ejection method, cooling layout, etc.