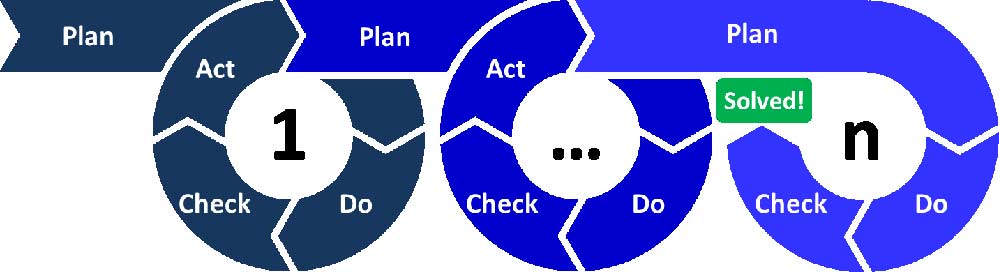

We follow the PDCA management. It is good solution and system for normal mold and urgent mold making. We offer Weekly Report for mold making quality control and on time deliver.

The four phases are:

- Plan: identify and analyze the problem or opportunity, develop hypotheses about what the issues may be, and decide which one to test.

- Do: test the potential solution, ideally on a small scale, and measure the results.

- Check/Study: study the result, measure effectiveness, and decide whether the hypothesis is supported or not.

- Act: if the solution was successful, implement it.

Good quality is in every detail, every step, mold making, material purchase & inspection, machined & fitting etc.

Inspection machine and tools:

- 1 set CMM

- 1 set Optical Measuring Projector

- Hardness gauge

- Vernier caliper, micrometer, thick/thin plug gauge, screw gauge

- Toolmaker Microscope, height master, surface Plate

Inspection content:

- Customer’s Mold Specification Sheet Check

- Design Optimize control

- Mold Steel Hardness Inspection

- Mold Electrodes Inspection

- Mold Core and Cavity Steel Dimension Inspection

- Mold Pre-Assembly Inspection

- Mold Trial Report and Samples Inspection

- Mold Pre-Shipment Final Inspection

- Mold Package Inspection

Quality Partner: