Plastic injection mold making flow

Plastic injection mold making flow could be consider into: Mold Design-Mold Making-Mold Trial-Mold Packing & Shipping.

When you have a idea, and want to make it in real in to plastic. You could make 3D printing first to see what it is. After that it is time to make mold for it, if you want to make mass molding production.

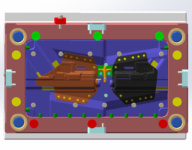

Mold Design

Mold design is including DFM, Mold Flow Analysis, 2D Mold Layout and 3D Mold Drawing. It is part lay out, part line making, gate design, runner design, gating way, ejection method, cooling layout, etc.

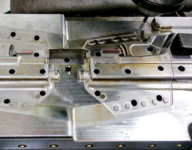

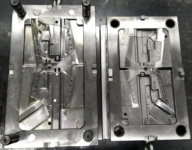

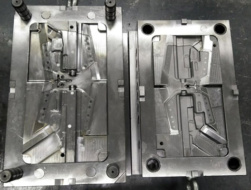

Mold Making

Mold making is based on mold making and purchase mold base, steel and component by machined by CNC, EDM, Lathe, Gun Drill and Milling etc., make mold fitting and mold trial in the end. To see the idea into real by mass production.

Mold Trial

Mold trial is the last processing to check if the work is making well. You will get the molded part to inspection specification. Make decision if itt is ok or NG after mold trial.

Mold Packing & Shipping

Plywood for packing and 2D, 3D Mold drawing and electronic copper should be together with mold shipping.