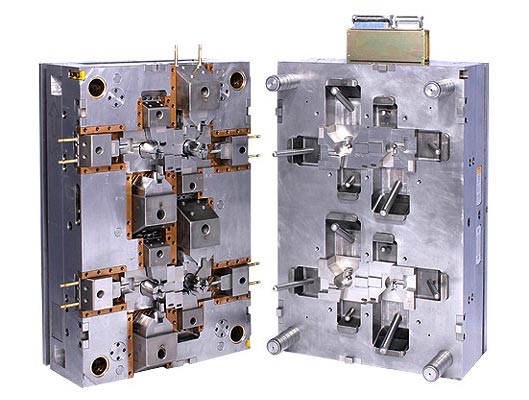

Hot runner mold is use hot spruce for injection molding, there is no waste of plastic, as it is no runner. It could save plastic, decrease cycle time, easy for production. Hot runner mold is most use for mass molding production.

Product Details:

- Product name: Hot runner mold

- Standard: DME Component

- Steel: H13 48-52HRC

- Plastic: PA66 + 30%GF

- Cavities: 1×4

- Surface finish: SPI D2

- Runner system: YUDO

- Cycle time: 65s

- Tolerance: +/-0.02mm

- Dimensions: 600 X 450 X 350mm

- Mold life: 1 million shots

- Lead time: 5 weeks

Description:

Hot runner mold, DME standard, H13 steel heat treatment apply in industry

Hot runner molded Part

Mold Design

Mold design is including DFM, Mold Flow Analysis, 2D Mold Layout and 3D Mold Drawing. It is part lay out, part line making, gate design, runner design, gating way, ejection method, cooling layout, etc.

Mold Making

Mold making is based on mold making and purchase mold base, steel and component by machined by CNC, EDM, Lathe, Gun Drill and Milling etc., make mold fitting and mold trial in the end. To see the idea into real by mass production.

Mold Trial

Mold trial is the last processing to check if the work is making well. You will get the molded part to inspection specification. Make decision if itt is ok or NG after mold trial.

Mould Precision Co., Ltd. is a high quality plastic injection mold manufacturer, with rich experience in hot runner mold making and manufacturing, with competitive price and on time deliver.