How do solve Venting Problem of molding defection

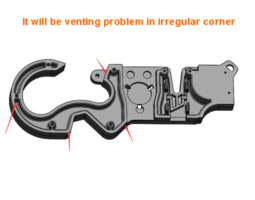

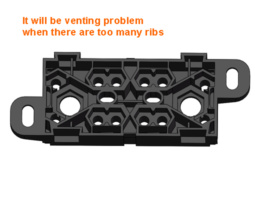

Venting Problem usually make plastic parts burned black. Add core or cavity pins is one good solution for solve Venting Problem. and even most difficult to adjust by plastic injection molding parameters. Mold design and making should make venting design even though when the part is very small.

It would be seemed as plastic mold developing defects. but in order to have successful plastic injection molds, then how to avoid these kinds of air venting problems?

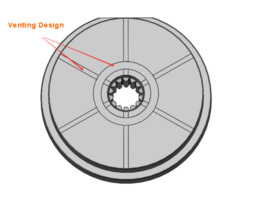

Modifications to the common core pin can be a simple solution

If you want to solve plastic mold air venting problem absolutely, then you need to do consider change plastic injection molds design.

For examples, for a plastic crate mold, mostly the air venting would be occurred on plastic crate handle area, as this area is the last material filling area and two types material would melt in this area. If you do not have air venting function design on mold, this area on plastic crate would easily burned and broken.

So usually on crate molds, this area would be design with inserts in blank, some time logo insets which would help for air to go outside.

This is only part solution to solve plastic mold air venting problem. We are professional in plastic injection molds making, if you want to buy plastic injection molds, pls feel free to contact with us.